Battery Load Tester Instruction Manual Simplified Check Program for Charging Systems The SB-5 2 is a variable load battery tester that provides a simplified check 2650-791X-10rH for alternator output and starter draw and circuit test. Auto Meter Products Inc. 413 West Elm Street Sycamore, IL 60178 T Toll Free (866) 883-TEST (8378) Fax (815)895-6786. Most of the manual ranging meters have a 20V range, which is what you need to test a car battery. The 20V range means it will measure between 0V and 20V. Tip: if you are a beginner looking how to use a multimeter to test a car battery to ascertain its voltage, consider getting one that has a dedicated battery tester range on it. This test identifies excessive starter current draw, which makes starting difficult and shortens battery life. Perform Battery Load Test - proceed if battery is 'Good'. ENGINE MUST BE AT NORMAL OPERATING TEMPERATURE 1. Connect tester clamps to battery as described in Steps 1-2 under Battery Load Test. Disable the ignition so the car will not.

On occasion, a battery may experience significant drain long after the engine has been shut off. The result can often lead to a flat, caused not by a faulty battery or through something obvious like the headlights being left on. It typically happens due to a short circuit that can be tricky to pin down.

Manual for TPR and Genisys Interface. Note: Genisys Requires System 4.0 for TPR Communication. The Premier “All-In-One” TPMS Tool! Covers 2012 Models! TPMS Tester Only SKU 09 ATEQVT55 TPMS Master Test Kit SKU 095059 1,24999 ATEVT55OBDII No Need to Purchase Additional Scan Tool or Other Accessories. This Tool Functions at the. 30 days, connect the battery to a tender using float-type charge technology to prevent sulfating - a cause of premature battery failure. Replace worn or missing battery hold down straps and pads to reduce the risk of battery damage and vibration. Switch ignition to OFF position and disconnect the battery when servicing electrical system components.

This is known as parasitic draw. A certain amount of draw is normal – in the region of 25mA (milliamps) – but if you have 100mA or more being lost, something is up.

It could be anything from a dimming dome light staying awake or glove compartment switch sticking on, to faulty aftermarket radio or alarm wiring. In addition, any number of fancy electronics systems that are installed on newer cars could be playing up, such as your GPS or proximity key system.

What You’ll Need

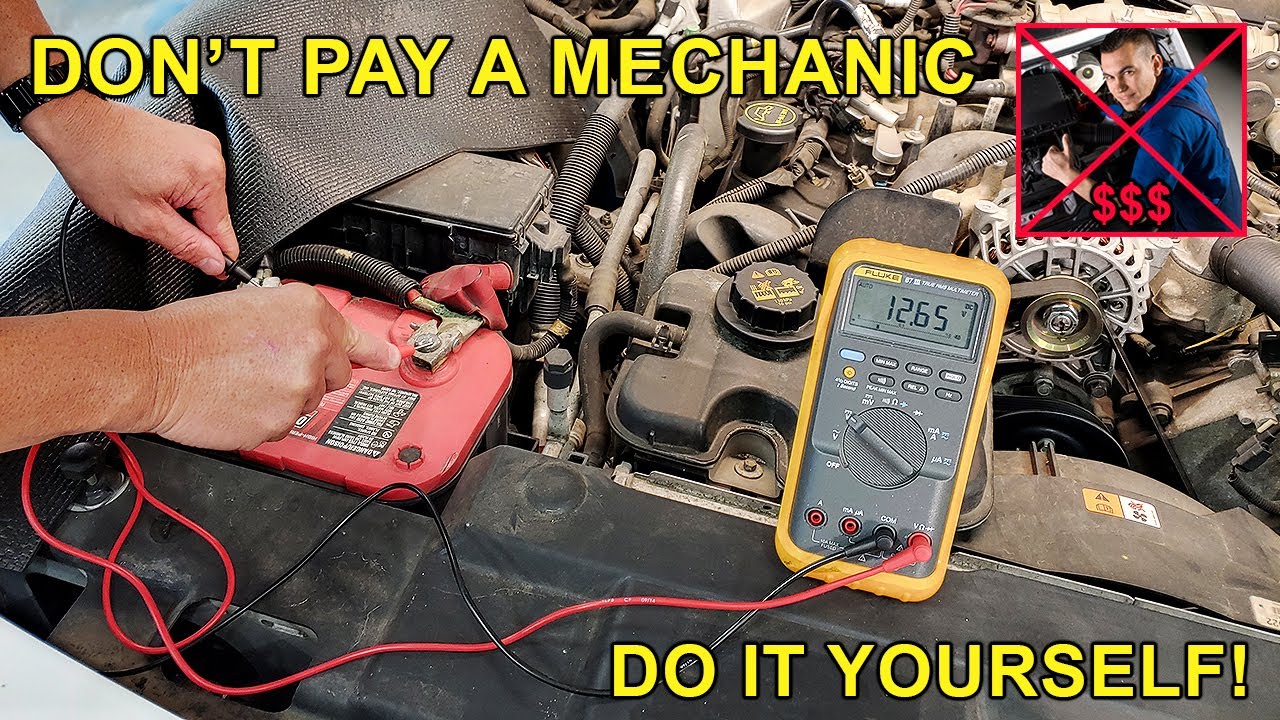

A digital multimeter is best for this test as opposed to an analog one, which is not as accurately read. A DMM with the ability to measure continuous current to 10A will be fine in most cases, though one rated 20A would be less prone to blowing a fuse. You also need a milliamp range for higher resolution to pick up minimal current draw as most faults tend to be of the trickle variety.

You can buy fairly cheap, half-decent multimeters these days, but bearing in mind that the cheapo, no-name ones are not known for their quality or input protection. It is best to stick with a brand name, though you don’t necessarily have to go with a top branded Fluke model.

Procedure

Step 1: Prepare for Test

You should have a fully charged battery before starting – voltage would be around 12.6V for a good one. Be sure to close all doors, turn off the radio and disconnect accessories, such as smartphones and add-on GPS devices. Even a key in the ignition can have systems waking up on newer cars that will initiate draw.

Step 2: Disconnect the Battery

Pop the hood and disconnect the negative cable from the negative battery terminal. It is always best to do a parasitic draw test from the negative side so there is no chance of accidentally shorting should you test from the positive side.

Step 3: Connect the Multimeter

Plug the black probe into the common (COM) jack input of the multimeter and the red probe into the amps (usually A) jack input. Then connect the red probe to the previously disconnected negative cable of the car loom, and the black able onto the battery terminal.

Note: in order to test for current, the multimeter must be connected in series with the circuit as it needs to gauge electron flow, so to speak. Voltage, on the other hand, is measured in parallel.

Step 4: Give the Car Time to Sleep

Modern car systems may ‘wake up’ when you connect a multimeter in such a fashion as it picks up the power of its batteries. So wait a few minutes before conducting the draw test.

CAUTION: when connected, avoid starting the engine or even turning on the headlights as this will likely blow a fuse in the multimeter. Vehicle batteries put out a lot of amps due to being low voltage.

Step 5: Reading the Meter

Newer, auto ranging multimeters will automatically select the correct range of a signal they pick up. On manual ranging meters, you will need to select a range, usually either 2A or 200mA. If you get ‘OL’ on the screen, it means over limit and you should select a higher range.

If you see a reading of around 50mA and above on a standard car, it generally means something is drawing power and you likely have parasitic draw. Just note that if you have a big, modern, luxury car its added computerized systems will likely increase the natural current draw. In this instance, the threshold might be 100mA.

PARASITIC DRAW ESTABLISHED

It is now time to see what is causing the draw. The tried and tested method is to start pulling fuses to see which circuit is the culprit. [For testing newer vehicles with complex systems, see below for a different method].

Step 6: Pulling Fuses

Locate the fuse panel(s) and start pulling out fuses one after the other, taking notice of any drop in the reading on the multimeter. If there is no joy with the fuses, start removing the relays. For those fuse boxes that are inside the vehicle, a tip is to lay the meter on the windshield facedown so you can see the display.

Step 7: Narrowing Down

When the display drops to a nominal mA draw, note the fuse/relay position number and check the vehicle’s manual. There is often more than one circuit on a given fuse, so you would then need to eliminate each one, such as remove a bulb or unplug a heater.

Step 8: Repair and Reconnect

When the meter drops down to 25mA or less after removing the offending fuse, bulb or unplugging a circuit, you likely have your culprit. Repair the fault/replace the item and run another test to be sure. If you’re confident there are no other faults, reconnect the battery.

Alternator fault?: if you’ve gone through all fuses and relays (and checked for other fuse boxes), oftentimes the alternator can be at fault. One of the diodes may have shorted out and caused current to drain back to the battery. Test it with the multimeter before and after unplugging.

Parasitic Draw Test on Newer Cars

Some of newer vehicles can be a real pain to diagnose parasitic draw test with a multimeter due to all the added electrical circuits, computers and control modules. You have electric mirrors, heated memory seats, GPS, trackers, and a slew of gadgets. Some of these systems are interlinked, exacerbating the problem.

Even car keys can indirectly cause current drain. Proximity keys are designed to wake up a car’s locking mechanism when they are within close proximity so that you can unlock and open the door without the key. This is great in normal conditions, say, at your house, but can be an issue in practice. If you park in an area where lots of other cars have these systems, for example, the computer may wake up every time their drivers walk past your car. In this scenario, you may need to disable the sensor. More on this issue…

Old vs New Method

The old method detailed above – disconnecting the battery, putting the multimeter in series and pulling fuses until you find the draw – might not work as effectively on these cars. This is because the very disconnecting of the battery may temporarily fix the issue by sending the system to sleep along with the error. You don’t want this; you want the fault to keep drawing current so you can diagnose it on your meter.

An alternative is to thus diagnose parasitic draw by measuring voltage drop across the fuses. You can do this in-situ as auto fuses have open test points on them, so no need to remove them or disconnect the battery. What you are looking for is a voltage drop in the millivolts range. It is caused by an increase in resistance brought about by the heating of the fuse through movement of current.

Different size fuses will show a different voltage drop, but all of the same rating will have roughly the same resistance, so it is easy to get a reference by testing one 10A fuse against the next. As an example, a 10A fuse with 1A flowing through it might show a voltage drop of 5mV. If you were to measure the same fuse with no current flow, it would be more like 0.1mV or 0.2mV. Quite significant and easy to spot.

Procedure

- Drive the car and operate all circuits – wipers, heater, seats, windows, GPS, lights, sat-nav etc – and then return and remove the key.

- Consult the manual on how long it takes for the various systems to sleep.

- Be sure to tape down the driver door switch that operates the dome light and leave the car unlocked so you don’t end up switching on any systems upon reentering.

- Carry out the testing of each fuse and note any spurious voltage drop.

Other vehicles: the above also works for motorcycles and other vehicles, with a similar process.

Key to Better Battery Life

Along with being a nuisance and potentially leaving you stranded, even minimal draw can wear down a vehicle’s battery over time, often leading to performance issues and possibly a slow death. The key to good battery life is to nip any parasitic draws in the bud and also ensure the battery keeps charge above 12.4V.

Vehicles that only see occasional use are more prone to losing charge, where sulfation further compromises performance and longevity. Those driven daily have the benefit of the alternator to maintain charge, and when you test the voltage and current frequently, you can pick up any potential issues early.

Conclusion

Parasitic draw on one’s vehicle can be a nightmare and often happens at the most inopportune time. But it needn’t be the mammoth task you initially envisioned and is wholly within the realm of the layman, as long as there is a multimeter to hand. You can take great satisfaction in diagnosing the fault yourself and potentially save hundreds of dollars in the process.

See here how to check battery charge

Choosing a Multimeter

There are a slew of multimeters on the market, from cheap Chinese-made testers and Craftsmans up to high-end Flukes. A basic device is all you’d need for a parasitic draw test with a multimeter. Just make sure it can test amperage, has an auto ranging mode, and is at least a known brand.

US brand INNOVA makes decent multimeters for automotive tasks, such as the 3340 or cheaper 3320, but even a standard electrician’s multimeter can do the trick. Do spend a bit of time going over the specs to ascertain functions and the electronic input protection. This is especially important for the multimeter and your health. Both meters mentioned are not fused on the 10A input, for example, whereas the Fluke 77 IV is.

INNOVA 3320

Customer complaints surrounding flat batteries are common throughout the year with peaks during the winter season. Those who comment that their vehicle fails to start after standing for a couple of days must set alarm bells ringing with reference to parasitic drain.

Battery evaluation is normally taken care of using automated devices or better still, the PicoDiagnostics battery test procedure where we test not only the battery, but the starting and charging system in one hit. Once the above are confirmed we must then focus our attention on battery drain and parasitic current draw.

This test is often overlooked yet should conclude any customer complaints surrounding non-starts as a result of a discharged battery. We can traditionally evaluate both a battery starting and charging system very quickly indeed but parasitic drain demands a prolonged test (30 minutes is common for a modern vehicle to shut down and move to sleep mode).

For those vehicles with a history of battery discharge you may choose to monitor the parasitic drain overnight or even a number of days. This itself presents a challenge surrounding current clamps.

Given our Pico current clamps are powered by an internal battery with a continuous operational time ranging from 14 to 16 hours (new battery installed) we most certainly run the risk of erroneous results during prolonged parasitic tests (not to mention the time the customer’s car is off the road).

I think it is worth mentioning here how a current clamp operates in relation to the values we capture on our scope screen.

The current flow through a conductor has the valuable side effect (in our case) of producing a magnetic field about the conductor. By closing the jaws of our current clamp around the conductor the magnetic field can be detected and converted into a voltage directly proportional to the strength of the magnetic field. The voltage is then sent to the scope and displayed on screen as a current value. Prior to connecting the clamp around the conductor a zero operation is carried out to ensure accurate display of current values and a true zero point reference. This is achieved by pressing the zero button on the clamp, which charges a capacitor within the clamp removing any DC offset value.

The TA018 clamp in the image below has a conversion factor of 100 mV/A.

Figure 1

In order to obtain accurate readings during prolonged parasitic drain tests we must be aware of the operational characteristics of inductive-style current clamps. I am referring here to drift.

While we confidently set our current clamp to zero before taking any measurement, prolonged measurements will highlight drift in the form of our readings drifting away from the actual value.

For example zero amps measured at 20:00 may be 80 mA at 08:00 the following morning, and when measuring parasitic drain an 80 mA error could mean the difference between a pass or fail sending the technician on a wild goose chase. Any measurements taken are only as valid as the accuracy of the equipment used and so being aware of the following tips will reduce the impact on our results associated with drift.

Tools Battery Draw Tester Manual Download

- Temperature and environmental conditions are the biggest offenders when we refer to drift. Store your current clamp in the location it will be used to carry out the measurement. Not in a warm office then used in a cold workshop (acclimatize your clamp to the test environment).

- Ensure the clamp is used away from sources of environmental noise.

- Be aware of the minimum operating temperatures of the current clamp (0° C).

- Ensure the clamp's internal battery is prepared for overnight testing - this may require a new battery.

- Switch on the current clamp and allow the device to warm up (approx. 10 minutes).

- The current clamp can be installed to either the battery positive or negative lead but ensure the correct orientation of the clamp (refer to arrow on clamp jaws which indicates direction of current flow).

- Ensure the vehicle is locked and all keys are out of the detection range of any Keyless/SMART entry systems. Customer keys within the detection range of the vehicle will prevent total shutdown of the vehicle network.

- Using the zero function of the clamp is essential for accurate measurements; however, for overnight testing you may opt for the technique below:

The principle of zeroing the current clamp relies upon the charging of a capacitor within the device to remove any DC offset value. The capacitor has the potential to discharge overnight (varies between clamps) so resulting in drift away from the actual measurement value. An option here with PicoScope is to switch on your current clamp and wait for the 10 minute internal warm up to elapse (do not zero the current clamp).

Connect the clamp to your PicoScope and select the relevant probe setting (60 A Current clamp [20 A Mode]) from the Channel options menu. Select the relevant input range which will depend on the style of vehicle. ±1 A will cover you for the majority of measurements once the vehicle has completed the door locking/security phase.

With the waveform on screen you will notice the current value is not at zero amps as we have not zeroed the clamp (by choice). Here we can now use the PicoScope software to carry out a zero offset procedure by clicking on the Channel options button and selecting Zero Offset. PicoScope will now ask you to short the BNC terminals of your chosen channel together (this would normally be a x1 test lead).

At this point click OK inside the Zero Offset dialog box and the scope will now adjust the output value of your current clamp to zero. Here we used an alternative to using the zero function of the current clamp so bypassing the capacitor discharge issue inside the clamp when overnight testing.

Remember, after completion of your overnight testing, select the Channel options button and click the Clear button from the Zero Offset menu. This will restore your scope channel to factory setting with reference to zero offset.

Figure 2

Figure 3

With your clamp prepared you can now connect around either battery lead to commence overnight monitoring of the vehicle parasitic drain. Below we can see the shutdown period of the vehicle where the parasitic drain was out of specification for over 23 minutes (typical for modern vehicles).

The final parasitic drain confirmed the vehicle to be in specification sleep mode for over 8 hours at 47 mA (80 mA being the arguable recommended maximum value).

Figure 4

When monitoring parasitic drain we are only looking for the average of very low current values (below 80 mA). Such low values are always susceptible to noise and so you will find that low pass filtering will be essential to measure the average value of concern. Periodic spikes visible during parasitic drain measurements are often attributed to security LED operation or keyless entry systems looking for the vehicle keyset.

Whilst they are visible, they tend to pulse at very rapid intervals (high frequencies) and when averaging out the peak values of these pulsations, they have a negligible contribution to parasitic drain. Such pulsations will eventually halt as part of deep sleep mode built in by manufacturers to protect the vehicle battery during prolonged periods of vehicle inactivity (airport parking springs to mind here for instance).

Tools Battery Draw Tester Manual Pdf

To capture such high frequency spikes you will be required to set a high sample rate over long time frames resulting in very large file sizes.

As a general rule of thumb: Sample Rate is equal to the Number of samples across the screen/ Time span across the screen:

Figure 5

In order to view the sample rate and other properties surrounding your scope/capture, select Views and View Properties. The Properties box will now be displayed on the right side of the screen, highlighting the relevant information about your scope settings. Adjusting your number of samples and timebase will reveal a sample rate in the Properties panel. This allows you to ensure a sample rate is set appropriate for your capture ensuring you miss nothing, while providing you with a manageable file size containing the data of interest.

To conclude: Parasitic drain testing cannot be ignored and must conclude our test procedure when investigating complaints surrounding flat batteries. Whilst the procedure will extend the diagnostic time involved it will most certainly pay dividends to the customer and or workshop and avoid embarrassment from returning customers who may have been sold a battery on a prayer.

Hi, can you use the 200/2000 Amp clamp also for this battery drain test as the jaw is alot larger and easier to put around the battery cables?

I have a Fiat with fuses with no small test points.

What test can be used in place of the voltage drop test other than pulling individual fuses.

Hi

I have a Fiat Panda 1.2 Dynamic Euro 4 2006.

There are 2no. fuse boxes, one in the engine compartment and one inside the car. All the fuses do not include the small access test points as described in the article.Therefore the non-intrusive fuse voltage drop test procedure cannot be adopted.

What is the alternative procedure for testing in this situation ?

A clear to understand article giving a good practical way of using the current measuring capabilities of the Picoscope.

The calculation in the example needs the units correcting. Its not 53.9%, rather 53.9 Ah.